Scope and Intent

In short, this is a shelf designed to fully automate the light, water, air, and fertilizing of plants while I was away for winter break. It was a simpler spinoff of a design I worked on with a friend who did plant research. In addition to being used for a small experiment, I used it with pretty good success to grow a bunch of loose leaf lettuce which ended up actually being more than I could give away to vegan friends, and the food pantry wouldn't take it (understandable) so my college roommates and I would feed various animals and eventually tried blending it into a juice. As a cautionary note: I also tried cloning basil, but the store bought stuff always seems to have some sort of problem after a week or so. It made sense to eventually switch to full hydroponics starting from seeds.

Design

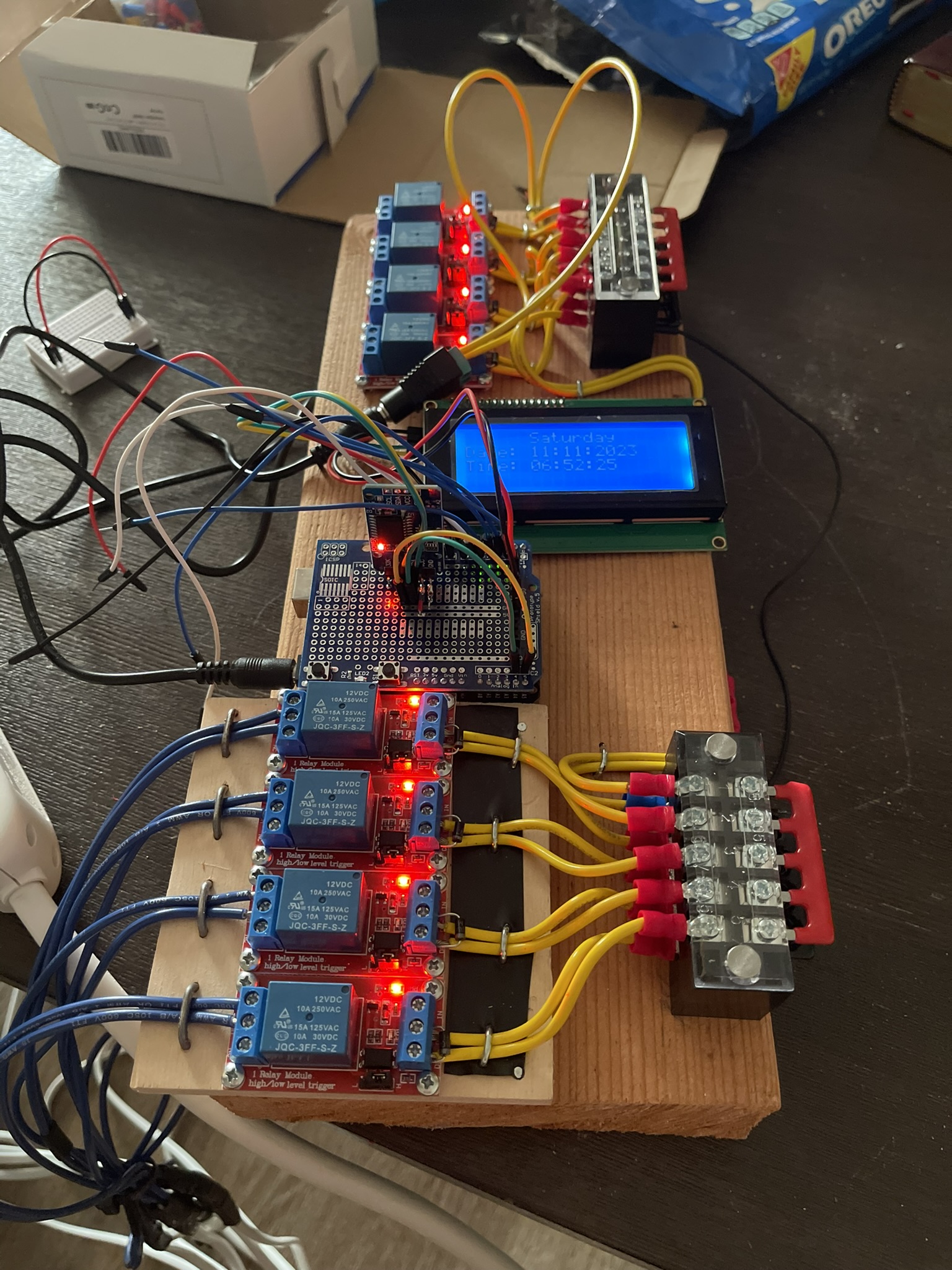

The project itself fundamentally boils down to 1. Making a schedule for the program to check against 2. Controlling the hardware via microcontroller 3. Assembling the physical parts, and 4. Setting up the LCD/button interface to view and modify schedule/action values I really wanted to be able to control all of the environmental factors on a time-controlled relay board, which ended up being a physical 2x6 that everything was attached to. I know I could have used transistors, but to some degree, I just liked the clicky noise and the feedback that things were working as intended. The relays interestingly needed diodes in parallel with the relay (bridging the control power side) to prevent "flyback" voltage spikes when powered off. This was something I thankfully learned before the project was fully assembled. If you have a project with solenoids or relays, or both, I would consider if flyback diodes are needed to protect your controller.

Assembly

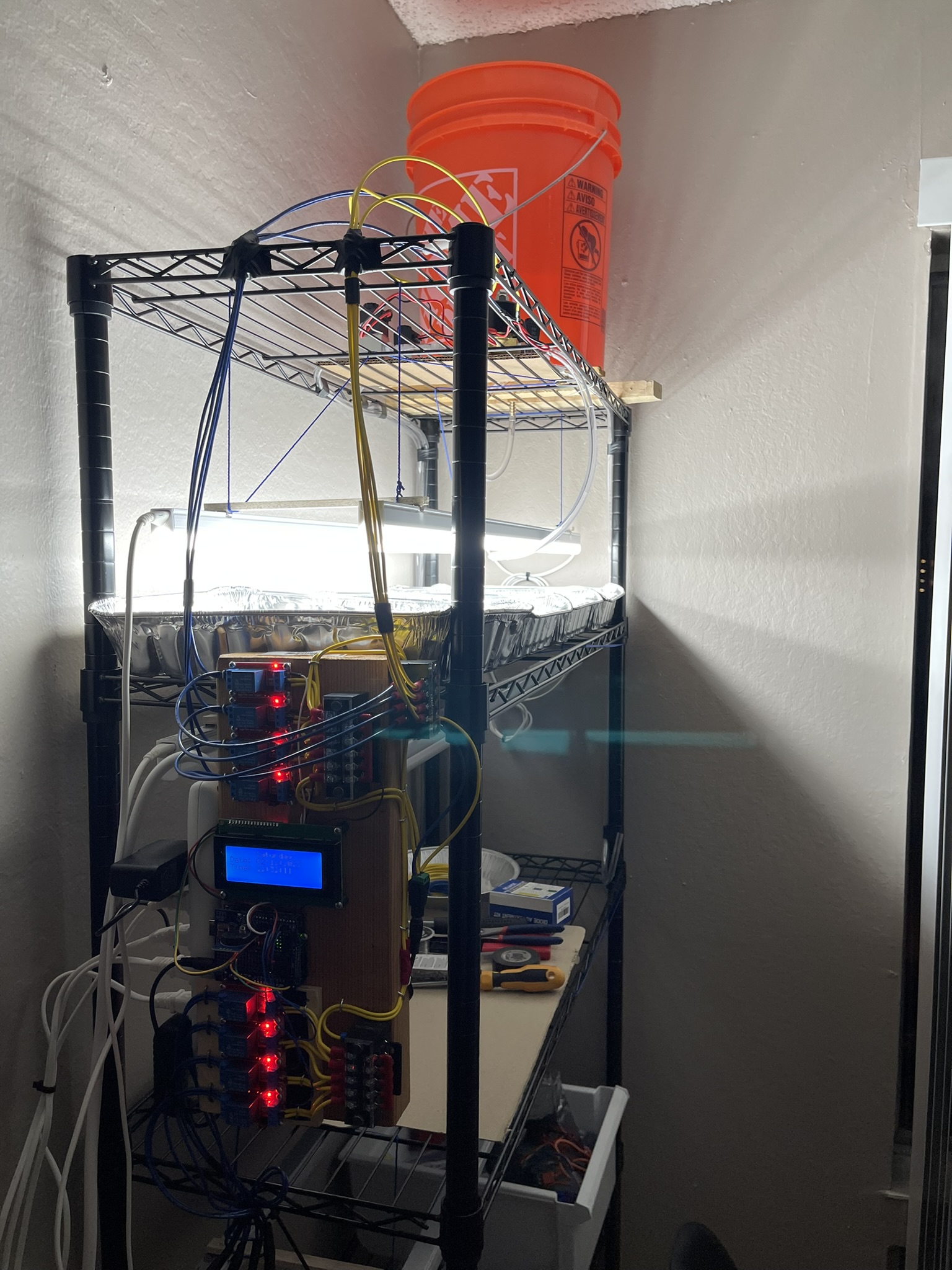

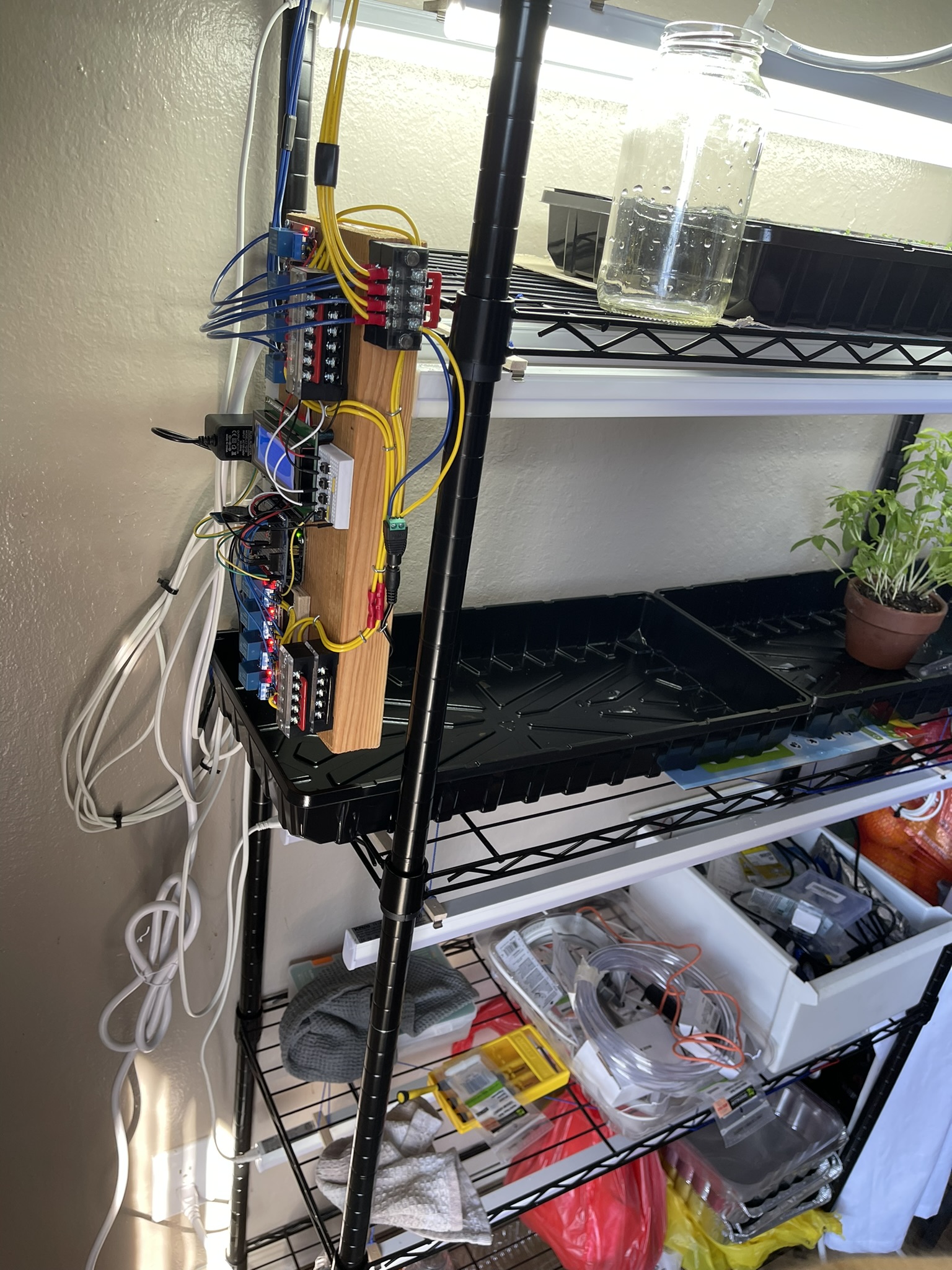

Briefly, the LED lights were simply mounted to the underside of the shelves with a string that could be adjusted to change height. They generated virtually no heat. The water was controlled by a central reservoir with four solenoid valves leading to each shelf's tray where plants were bottom watered. This design was partially inspired by a system used in my research lab at the time to "water" mice. An interesting problem at this stage was finding a way to evenly distribute water among different trays on a given shelf. I found restricting flow at a T splitter at the bottom worked well enough. While this design was originally manually calibrated for water frequency based on plant consumption and growth, one could easily use some measure of conductivity to see if water is present, and then start a countdown timer to see how long to wait before watering again. I eventually also added alternating direction fan control as in a plant class, I learned that a hormone I have since forgotten makes stems more rigid in the presence of wind. Early lettuce crops were quite floppy.

Updates

- Date N/A: Some may be horrified when seeing the shelf control panel as it is not only a mess of wire, but an electrical risk should water get on it! This is absolutely correct, and while all the wires in the photos had drip loops at the time, I got some early feedback and changed the design to better protect the electrical side.